The University of Granada and IFMIF-DONES España Consortium receive the first prototype particle accelerator

Posted on |

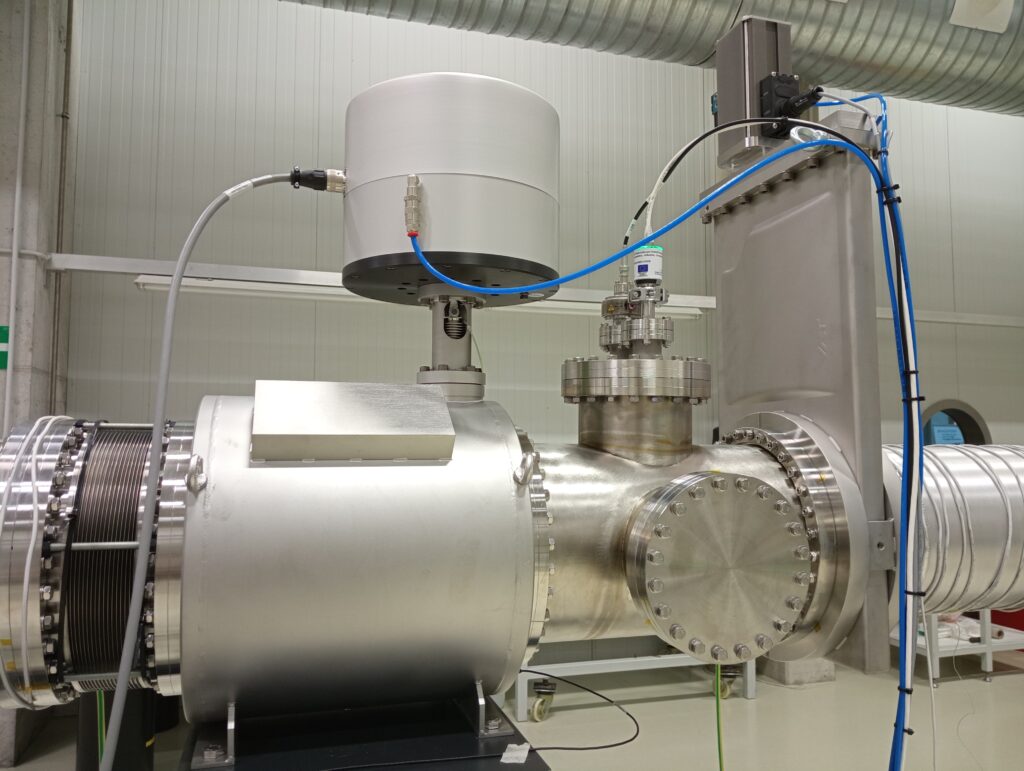

The MuVacAS (Multipurpose Vacuum Accident Scenarios) facility, a scale prototype of the last 30 metres of the particle accelerator’s vacuum chambers, has been received by the University of Granada and the IFMIF-DONES España Consortium

MuVacAS is currently operative in the facilities of Tekniker, in Eibar, Guipúzcoa. In the next months it will be transported and installed in the UGR-Laboratory in Escúzar. In this way, it will be the first high technology equipment (together the STUMM-Proto) that will be installed in the IFMIF-DONES site. During the coming years it will be used to carry out different experimental campaigns, equipment validation, and support the training of personnel in high vacuum technology by the involvement of PhD students and technicians. It is therefore a seed of the future high vacuum laboratories that will be essential for the construction and operation of the IFMIF-DONES accelerator.

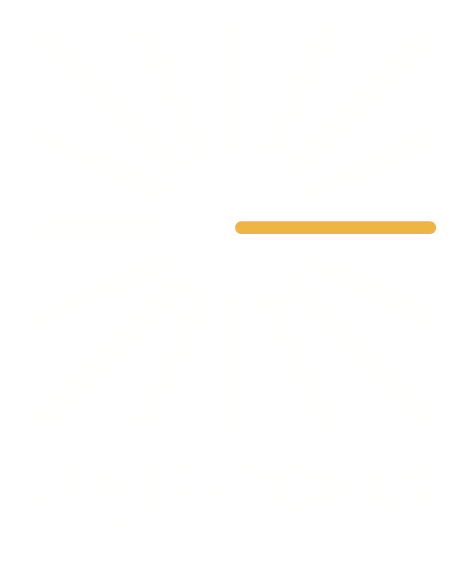

Its objective is to validate high vacuum technologies required for the accelerator since, without this vacuum, the accelerated deuteron beam would be lost in a few meters due to collisions with the air the residual gas molecules. The technologies that shall be validated include, among others, pumping groups and their distribution in the line, sensors, vacuum valves and protection mechanisms in case of system failures. For example, leaks or ruptures in any point of the vacuum line.

These leaks or ruptures in the chambers could lead to the formation of shock waves due to the great amount of gas that can suddenly enter. The mechanism to mitigate these events consists in the integration of the so-called “Fast Isolation Valves”, which are able of closing in less than one ten of a second and isolate the zones of the accelerator vacuum line in which the leak has taken place. It is important, in any case, to know the amount of air that would “scape” to the closing of these valves since, even if they close very fast, the shock wave can travel at speeds well above of 1000 m/s.

This is why we are interested in studying these processes and times of shock-wave generator to predict and measure its speed, and validate if our protection system work in time.

To reach the vacuum pressure of 10-7 mbar (o.ooooooooo1 times the atmospheric pressure), we use “hoovers” or technically-speaking “Vacuum pumping groups”. A very sophisticated component of these groups is the so-called turbomolecular pump. They are like a turbine, with inclined blades that turn more than 1000 times per second, hitting and pushing to the exterior the few lonely molecules that travel dispersed in the inner vacuum of the accelerator “pipe”.

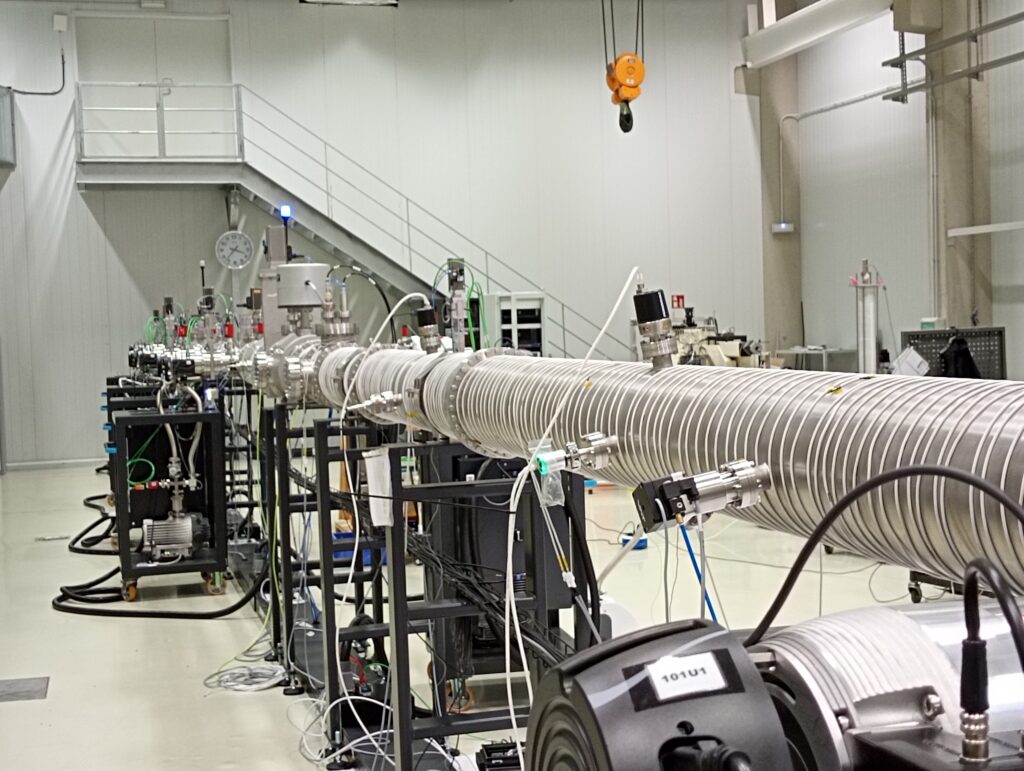

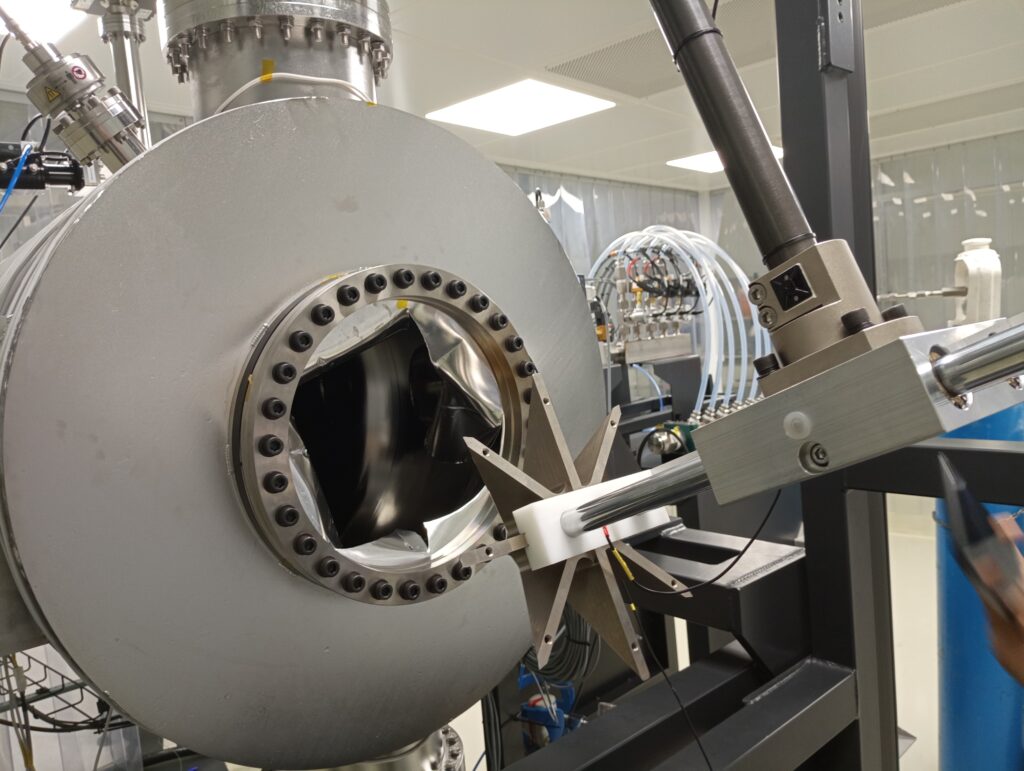

To simulate leaks and sudden gas inrushes, MuVacAS counts on two types of emulators. One of them is an injection gas module, like the one of the figure, which can quickly introduce (in milliseconds) different gas flows, precisely measured to help us to study the associated propagation times.

The second module is designed to simulate a sudden rupture of the target vacuum chamber. To do so, a “pendulum-punch” system is used, which can perforate an aluminium foil that closes this vacuum chamber.

To measure and study these inrushes of gas in the vacuum in all these experiments, MuVacAS counts on a great amount of fast acquisition instrumentation, which has been specially developed to measure vacuum pressure changes in less than 0.1 ms. In addition, extensive instrumentation to measure the shock wave propagation such as accelerometers or strain gauges are also used.

You can get an inside look at the installation in this video.