Accelerating towards fusion: The LIPAc accelerator

As already mentioned in previous issues, the future IFMIF-DONES facility requires a linear accelerator with very high power and current. To test and validate the technology of these machines, and as part of the IFMIF/EVEDA project, the LIPAc accelerator (Linear IFMIF Prototype Accelerator) has been installed in Rokkasho (Japan), capable of reaching a power of 1.125 MW, accelerating protons or deuterons with currents of up to 125 mA and energies of up to 9 MeV. These demanding power, energy and current requirements pose a huge challenge for the design and development of equipment and components, with a technological demand that is at the frontier of knowledge.

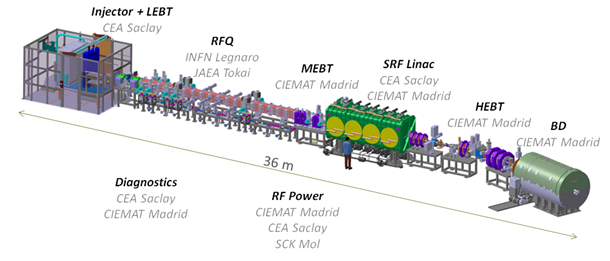

The commissioning of LIPAc, whose first subsystems were moved from Europe to Japan in March 2013, required an integration programme and considerable coordination, precisely because of the different countries of origin of each delivery:

- LIPAc’s various components [Injector, Radio Frequency Quadrupole (RFQ), Low, Medium and High Energy Beam Transport lines, Superconducting RF Linac, Beam Dump systems, 175 MHz RF systems, Local Control systems, Beam Control Instrumentation] were designed, manufactured and tested in multiple European laboratories (CEA, CIEMAT, INFN, SCK-CEN).

- The conventional facilities (main building, auxiliary and plant systems) and the Central Control System were provided by JAEA (Japan).

Layout of IFMIF accelerator validation facility with the indication of the different laboratory contributions

Specific databases, systems and management procedures for documentation, interfaces, assembly and 3D installation configuration were implemented as essential LIPAc features.

The LIPAc beam is generated by an injector using a deuteron source (D+). The D+ beam, after being correctly focused and filtered along the Low Energy Beam Transport line (LEBT), is accelerated by two successive systems: a copper RFQ and eight half-wave superconducting resonators (HWR), both located in the superconducting RF Linac (SRF). After control and measurement of the beam parameters, the D+ current is stopped by a high energy stop block (Beam Dump). Between these two systems, both beam transport lines, Medium-Energy (MEBT) and High-Energy (HEBT), transport the beam and adapt its properties to the downstream components. Amplifier chains, which are part of the RF Power System, based on tetrodes and solid-state RF amplifiers, provide the necessary RF power. In addition, a Cryoplant maintains the SRF Linac at a temperature of 4.5K. Instrumentation to control and establish beam diagnostics is distributed throughout the machine.

The building to contain the accelerator, which was constructed in Rokkasho and completed in March 2010, consists of an accelerator vault, heating, ventilation, and air conditioning (HVAC) zones, a heat exchange and cooling water zone for the controlled and non-controlled radiation zones, an access hall, a control room, and a large room for the RF systems (high-voltage power supplies and RF power chains) and the 4K Cryoplant. The walls and ceiling of the accelerator vault are made of 1.5 m thick concrete.

Certainly, the future IFMIF accelerator will be the most powerful Linac in the world. However, LIPAc, which is its prototype, already leads the world’s Linac power range and holds the record for particle current (125 mA).

IFMIF will be one of the most powerful accelerators in the world (in fact LIPAc is the most powerful accelerator currently in operation) and certainly the one with the highest beam current).

In summary, the first phase of the operation involved characterizing the proton and deuteron source up to a current of 125 mA. The next stage, with ions accelerated up to energies of 5 MeV, tested the efficiency of the radio frequency acceleration system (called RFQ), the medium energy beam transport system (MEBT), the RF systems that feed them and the beam diagnostics module (DPLATE). Under the overall coordination of F4E, CIEMAT (Madrid, Spain) is participating in this phase – together with CEA (Saclay, France) and INFN (Legnaro, Italy) – by supplying and setting up the RF systems, MEBT, DPLATE, the high-energy transport line (HEBT) and the high-energy stop block (Beam Dump), as well as contributing to the design and construction of components such as the superconducting Linac (SRF) and part of the control instrumentation located along the accelerator.

It should be noted that the experimental prototype diagnostics and instrumentation, as well as the MEBT and several key components of the RF systems are identical to those that will be used in the IFMIF-DONES facility. The successful validation of the LIPAC technology and performance is therefore vital for developing the neutron source required to qualify candidate materials for future fusion reactors.

We continue to take firm steps towards the control of fusion as a safe, clean (non-CO2 producing) and virtually inexhaustible source of electrical energy.